58 series

All-round machineMixing of crop residues

Reduction of CO2-footprint

Combining passes

SPADING IS MORE THAN JUST TURNING THE SOIL

More than 60 years of experience with spading machines is something Imants can look back on. From that experience we learned spading is more than just turning soil. Much more, in fact. Spading means mixing organic material with the living topsoil, incorporating crop residues and creating a seedbed, mixing green manure so it can be broken down into nutrients for the next crop. In short, both above the ground and in the soil you will achieve an even, homogeneous and well aerated soil after tillage with Imants spading machines. The true one pass tillage tool.

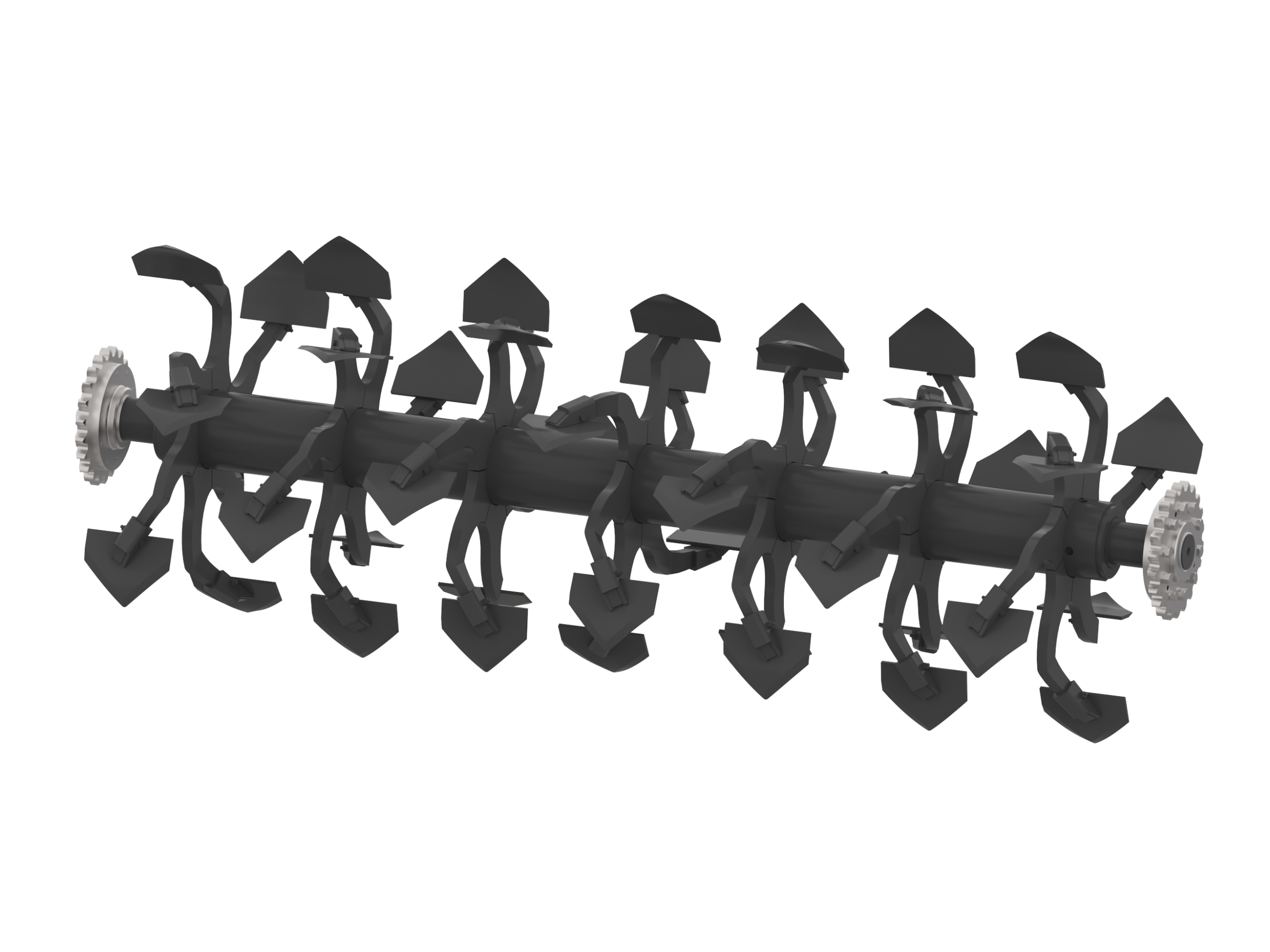

THE DESIGN OF THE SX-SPADING MACHINE

The SX spading machines from Imants are rotary spading machines. They work the soil by means of spades which are attached to the spading shaft via a steel arm. On the 58 Series, 6 spade arms create a bank. The number of spades on the spade shaft varies according to the working width.

Depending on what you need on your farm Imants can recommend the right spading machine. There are spading machines that can work shallowly (12 cm (5”) deep) but as well as very deep (up to 135 cm (53”) is possible.

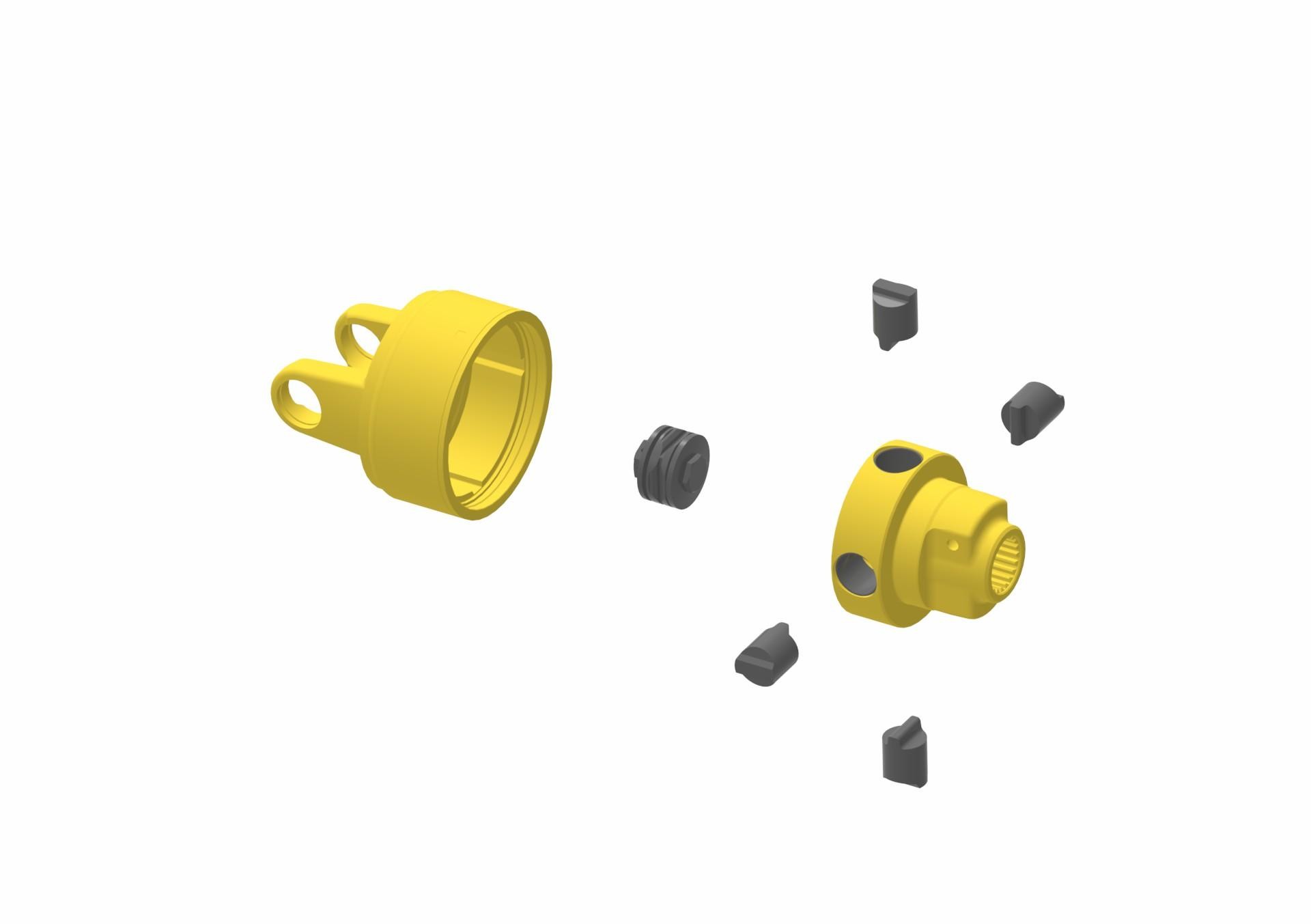

The SX-spadingblade

For use on all soil types except wet clay. The spading blades are easy to replace.

The spading machines are equipped with a cam clutch on the PTO shaft. This provides protection for the driveline.

Drive line of the 58 Series with driven power harrow.

SUBSOILING, YES OR NO?

SX SERIES

The SX-Series has a minimum working depth of 15 cm (6”), with a maximum of 35 cm (14”). The blades loosen the soil over the entire working width and mix manure, green manure or plant residues through the most biologically active part of the soil.

WX SERIES

The WX-Series is equipped with adjustable ripper legs between the banks, which can loosen the soil deeper than the spading depth. The WX-Series has fewer spading blades than the comparable SX-Series version, but the soil is still worked across the full working width. The ripper shanks loosen compacted layers of soil below the working depth of the spade shaft so that roots can also penetrate deeper into the soil resulting in a higher yield.

WHAT FINISH WOULD YOU LIKE TO HAVE?

Driven power harrow

The Imants 38 series spading machines can be equipped with a driven power harrow. This harrow breaks up the top layer and ensures a fine and even seedbed. It is the ideal roller for sandy and loamy soils.

Ringroller

The ringroller with a diameter of 60 or 80 cm (24 or 31”) leaves a coarser seedbed and is suitable for all soil types.

Prismaroller

For heavier soil types the self-cleaning prismaroller is recommended. This roller consolidates and culti-packs the soil so that a even, flat and firm seed bed is left behind.

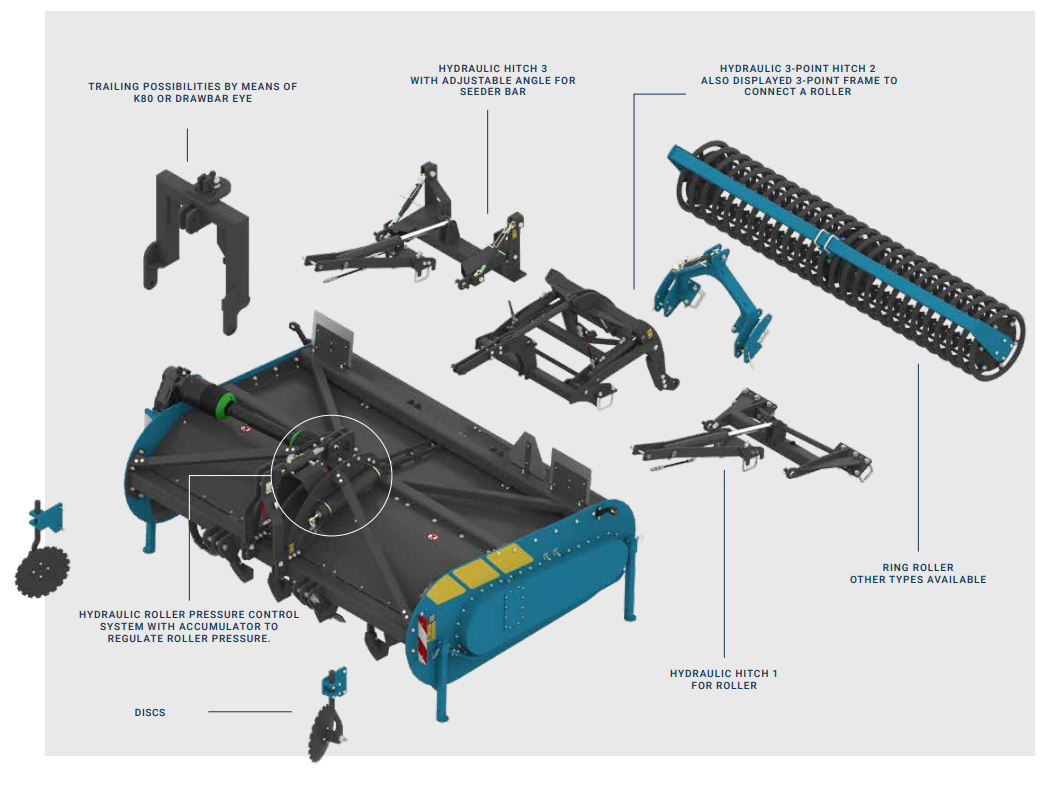

OPTIONS FOR ALL SX/WX MODELS WITH POWER HARROW

To make the SX/WX-Series spading machines fit your needs, you can choose from a number of options. You can not only choose from a number of different finishing rollers, but also from different types of hitches for mounting seeders or planters or different types of towed implements (drawbar or K80 ball).

In order to prevent crop residues or green manure from dragging on the side plates, the SX/WX-Series spading machines can also be equipped with discs. These guide the organic material towards the spading shaft.

The image below shows the 48 series. Please contact us for options for the model of your choice.

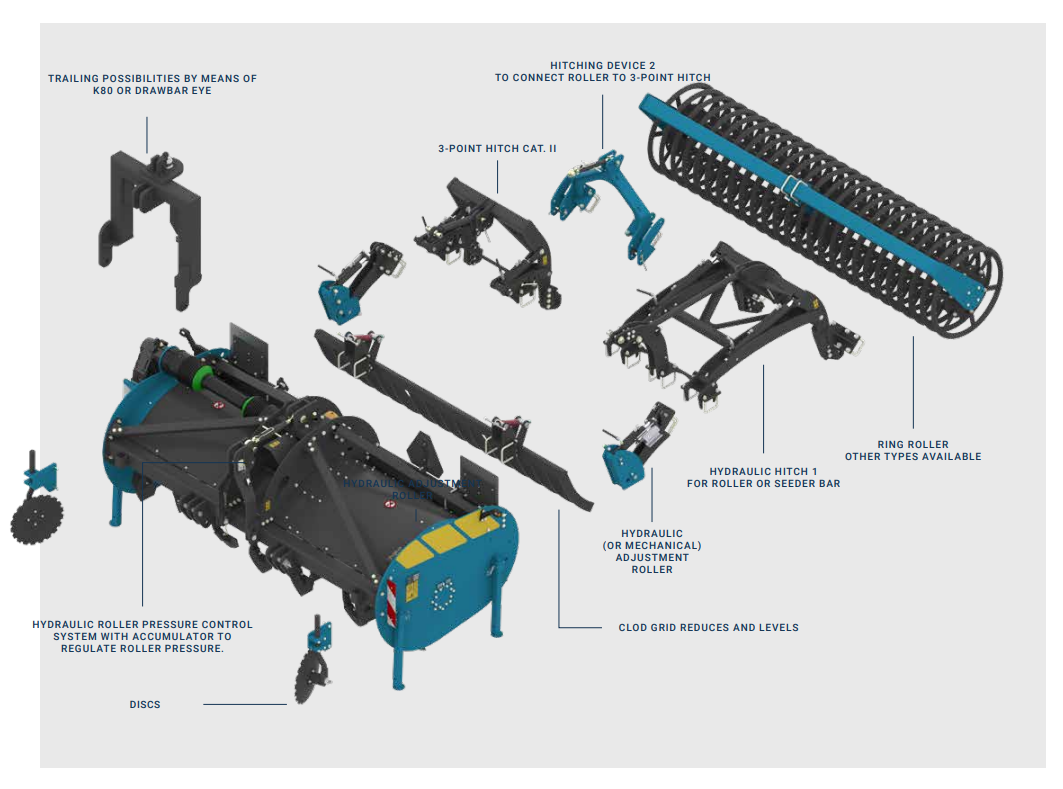

SX/WX OPTIONS WITHOUT POWER HARROW

The SX/WX-Series spading machines without power harrow can be equipped with a clod grid device to further reduce and level the ground that has been spaded. In addition, you can also choose different types of ground driven rollers for these spading machines. In order to attach sowing or planting machines, the spaders can be fitted with a rear hitch.

The image below shows the 48 series. Please contact us for options for the model of your choice.

COMBINING PASSES

The SX/WX-Series spading machines can be used to prepare the soil for sowing or planting. But the spading machines can also be the heart of a combination allowing you to do all the soil prep and planting in one pass. A (Imants Culter) subsoiler loosens the soil before it is spaded and a seed drill or planter can be mounted or attached to ensure that all operations are done in one pass. Combining not only saves money and time but is also better for your soil. Here you can see some possible combinations.

MODELS OVERVIEW

Type |

Working width |

Total width |

# spades |

Minimum power (hp) |

Maximum power (hp) |

Weight* |

Harrow** |

Shanks |

58SX300H |

300 cm / 117" |

331 cm / 129" | 42 | 230 | 340 | 3850 kg / 8488 lbs | yes | no |

58SX366H |

366 cm / 143" |

397 cm / 155" |

48 | 230 | 340 | 4150 kg / 9149 lbs | yes | no |

58SX450H |

450 cm / 176" |

481 cm / 188" |

60 | 230 | 340 | 4650 kg / 10251 lbs | yes | no |

58WX300H |

300 cm / 117" |

331 cm / 129" |

30 | 230 | 400 | 4100 kg / 9039 lbs | yes | 5 pieces |

58WX366H |

366 cm / 143" |

397 cm / 155" |

36 |

230 |

400 |

4400 kg / 9700 lbs |

yes |

6 pieces |

58WX450H |

450 cm / 176" |

481 cm / 188" |

48 |

230 |

400 |

4900 kg / 10803 lbs |

yes |

8 pieces |

58SX300 |

300 cm / 117" |

331 cm / 129" |

42 |

200 |

340 |

2750 kg / 6063 lbs |

no |

no |

58SX366 |

366 cm / 143" |

397 cm / 155" |

48 |

200 |

340 |

3000 kg / 6614 lbs |

no |

no |

58SX450 |

450 cm / 176" |

481 cm / 188" |

60 |

200 |

340 |

3300 kg / 7275 lbs |

no |

no |

58WX300 |

300 cm / 117" |

331 cm / 129" |

30 |

200 |

400 |

2950 kg / 6504 lbs |

no |

5 pieces |

58WX366 |

366 cm / 143" |

397 cm / 155" |

36 |

200 |

400 |

3150 kg / 6945 lbs |

no |

6 pieces |

58WX450 |

450 cm / 176" |

481 cm / 188" |

48 |

200 |

400 |

3550 kg / 7826 lbs |

no |

8 pieces |

* Above weight is indicative without options and without roller (except the power harrow machines).

** Machines without power harrow can optionally be equipped with various other rollers.

ALL machines include: Walterscheid PTO shaft with Torque limiting clutch. Quick-change system for the spading blades (SX), LED lighting set and width warning signs.

Ideal speed: 6, 8 or 9 km/h , 4.3 or 5.5 m/h (1000 rpm). The actual driving speed may vary depending on the application or situation.

Want to know more?

Contact us. Call +31 (0)497 - 642 433 or mail to info@imants.nl.