JNC Rotavators

JNC rotavators

With over 135 years of experience, Imants can

safely say that it has learned how to optimize

tillage. The Imants rotavators are no exception.

With a quick rotating movement, working green

manure or crop residues superficially and

making the soil very fine, that is milling.

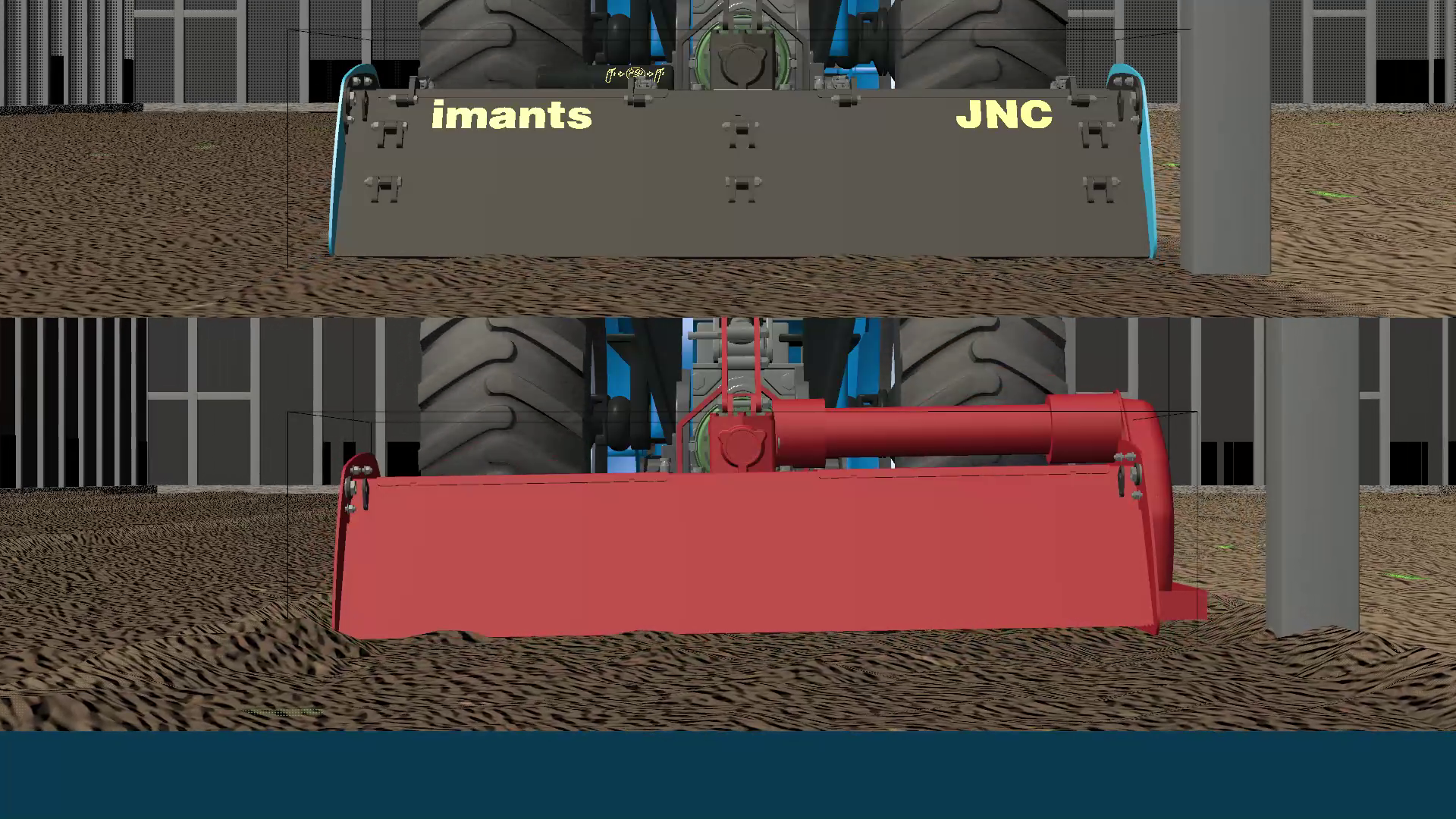

Imants JNC rotavators are unique in their kind due to the center drive.

Imants JNC rotavators are unique in their kind due to the central drive. As a result, the working width and transport width are equal and the soil is also loosened in the middle. Because there is neither a drive nor a skid on the side, the machine sinks evenly into the ground over the entire width. This is in contrast to a rotavator with a skid which runs on one side on top of the raw soil and on the other side sinks into the treated soil. This creates a skewed milling pattern with a ridge on the side.

This so-called “tile profile” has a negative effect. Finally, the lack of a side drive means that the JNC rotavator can work very close to obstacles. Think for example of the posts in a greenhouse.

Imants has 2 types of rotavators in its range.

A standard rotavator and an overtop rotavator

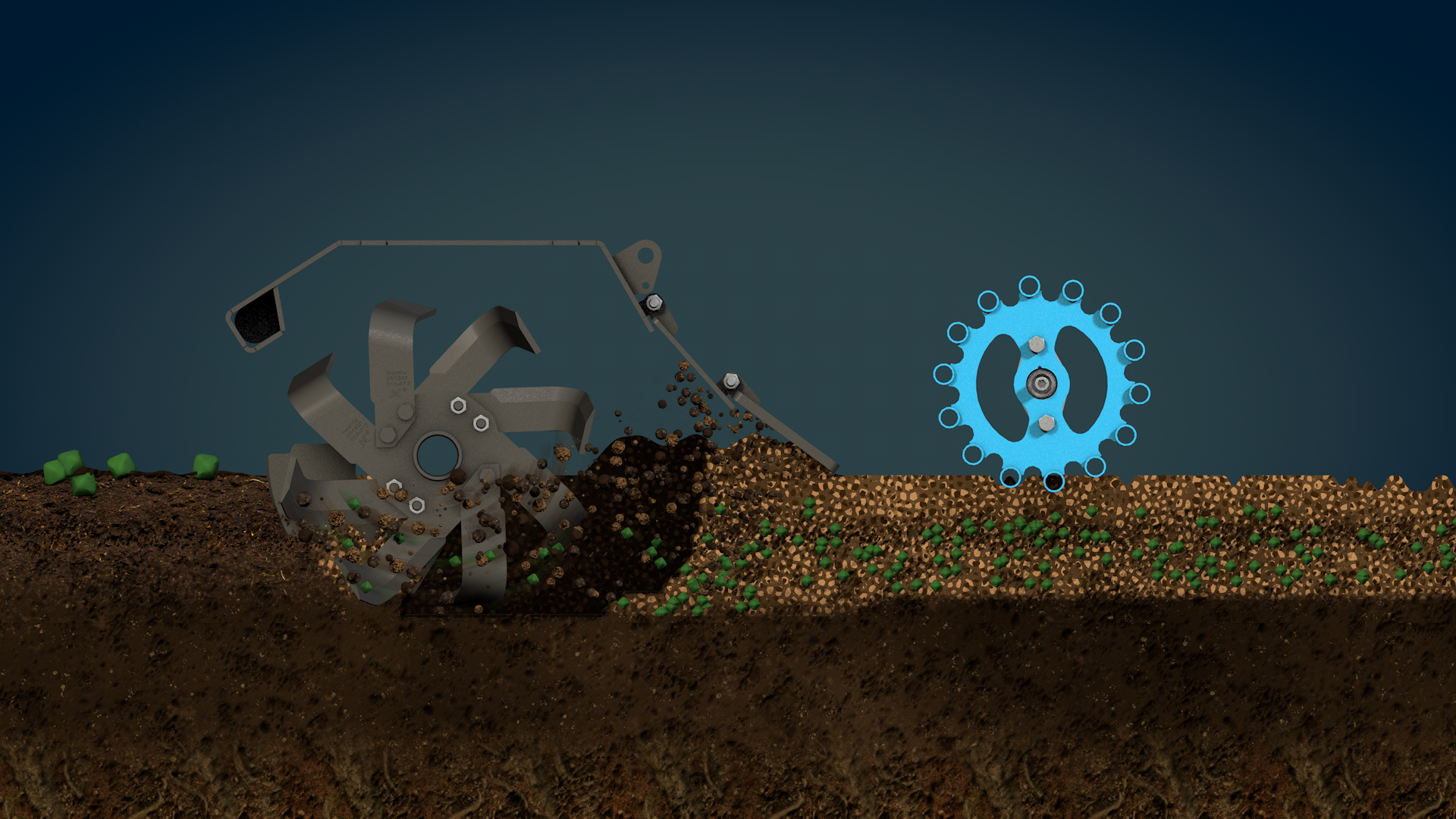

. The Imants standard rotavators work the soil

using Imants rotavator blades that rotate in the

direction of travel.

These self-cleaning rotavator blades have a special position that ensures that no rotavator sole is created. The Imants rotavator blades are made up of flanges. One flange consists of four Imants rotavator blades. The number of flanges varies according to the working width.

Overtop Rotavators

Imants overtop rotavators work the soil by using

Imants blades. These self-cleaning blades have

a special position which ensures that no milling

sole is created.

The Imants rotavating blades are made up of

flanges. One flange consists of four Imants

blades. The number of flanges varies according

to the working width. The overtop rotavators

rotate against the direction of travel while the

regular rotavators rotate in the direction of travel.

The self-cleaning blades have a special position that ensures that no milling sole is created.

Because these rotavators rotate against the direction of travel, the soil is thrown against a bar rack. Clods (and possibly stones or crop residues) are forced down by this bar rack, while fine soil is thrown through the bar rack. The result is that the soil is deposited even finer and in 1 working passage a clean seedbed is made.

Read more

Want to know more?

Contact us.

Call +31 (0)497 - 642 433 or mail to info@imants.nl.